|

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD

|

Gold Index: 8140

Separator device Wool Scouring Machine nozzle structure 5500 r/min

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Separator device Wool Scouring Machine nozzle structure 5500 r/min

separator

Separator device Wool Scouring Machine nozzle structure 5500 r/min

separator device

delivery instructions

KD510 separator

brief description

KD510 separator is mainly used in Wool wastewater craftwork, it is primarily used for extracting oil. The machine is nozzle structure. Continuous working, with high efficiency , greatly reduces the operating personnel's labor intensity

Parts of this type of contact with the material (except for mechanical parts such as drum: drum, drum lid, 2Cr13) are all adopt SUS304 stainless steel

This machine is inspected by the precise dynamic balancing, small vibration, long-running, safe and reliable

The workload: 10000-12000 L/h

Drum speed: 5500 r/min

Drum diameter: 460 mm

Separation parameters: 8000

Slag separation way: nozzle

Vibration speed: ≤4.5 mm/s

Noise pressure level: ≤90dB(A)

Whole machine weight: about 1200kg

Motor power: 18.5kW,3P/380V/50Hz

Overall dimensions: 1580mmX1060mmX1730mm

3, Equipment design, manufacturing, testing, reference standards

. the main standard of national machinery

JB/T8103-1999 Specification of disc separator

JB/T9095-1995 Centrifuges, separators and forging, welding, general technical specifications for Nondestructive testing

. national main standard

GB10894-89 separation of mechanical engineering law for the determination of sound power levels of noise

4,The main parts of equipment and material composition

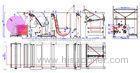

Main parts: access device , drum , transmission system , stainless steel cover

machine base , motor

(1) Frequency start, about 6-10minutes. Machine runs smoothly, low noise, little vibration, easy to install.

(2) The main stress components include drum and drum cover adopt 2Cr13, other parts in contact with materials such as disc all adopt 0Cr18Ni9 (SUS304)

(3) With stainless steel cover, adopt stainless materials

(4) Use cast iron for the frame

5, the scope of supply

separator) 1set

Motors, spare parts set of special tool set; certificates; a random factory data (including packing list, operation and maintenance manuals)

Separator start-up kit 1 set

- KD207 technical parameters

1.1

Type: KD207

Rated capacity: 4000 L/h

Drum speed: 6000 r/min

Slag separation: auto parts—ash

Speed of vibration: ≤4.5 mm/s

Noise pressure level: ≤90dB(A)

Motor power: 7.5kW ,380V/50Hz

Overall dimension: 1300mmX870mmX1430mm

Whole weight: 870kg

1.2 Equipment design, manufacturing, testing, reference standards

. the main standard of national machinery

JB/T8103-1999 Specification of disc separator

JB/T9095-1995 Centrifuges, separators and forging, welding, general technical specifications for Nondestructive testing

national main standard

GB10894-89 separation of mechanical engineering law for the determination of sound power levels of noise

1.3 The main parts of equipment and material composition

Main parts: access device , drum , transmission system , stainless steel cover

machine base , motor

(1) Friction start :about 5-8 minutes, Machine runs smoothly, low noise, little vibration, easy to install.

(2) The main stress components include drum and drum cover adopt 2Cr13, other parts in contact with materials such as disc all adopt 0Cr18Ni9 (SUS304)

(3) With stainless steel cover, adopt stainless materials

(4) Use cast iron for the frame

KD307 seperator

1,

KD307 separator is mainly used in purification of lanolin treatment. Parts in contact with the material are made of stainless steel material. This model is the separation of automatic slag removal machine, high separation efficiency, without having to disassemble parts of slag can be realized and can realize automatic control according to actual demand, greatly reducing the operator labor intensity

This machine is inspected by the precise dynamic balancing, small vibration, long-running, safe and reliable

2technical parameters

Rated capacity: 4000 L/h

Drum speed: 6000 r/min

Drum inner diameter: 355mm

Separated parameter: 8800

Slag separation: auto parts—ash

Speed of drum: ≤4.5 mm/s

Noise pressure level: ≤90dB(A)

Whole weight: about 860kg

Motor power: 7.5kw

Overall dimension: 1300mmX870mmX1430mm

6,

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)