|

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD

|

Gold Index: 8140

3-layer mesh-belt tensionless loose dryer

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

3-layer mesh-belt tensionless loose dryer

<span style="font-family:

3-layer mesh-belt tensionless loose dryer

KD-320 3-layer tensionless loose dryer

Quick detail:

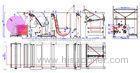

Chamber quantity: 4-chamber, 6-chamber, 8-chamber

Mesh belt layer number: one, two, three, four

Mesh belt width: 2400mm 2600mm 2800mm 3200mm

Mechanical speed: 3-45m/min

Evaporation volume: 180kg per chamber per hour.

Machine capacity: 4-chamber type: 100kw 6-chamber type: 144kw

Machine weight: 4-chamber type: 25 T

Chamber temperature: steaming heating: 100-140

Conducting oil heating: 100-170

Out dimensions: 6-Chamber type 16000*4960*3320mm

Feature

Speed controlled by frequency convertor makes the fiber over-feeded and sanforised by several times during the drying process of the fabric. Feel good, low shrinkage.

3-layer mesh belt with Taflon coated, forth and back long path drying, high efficiency, low cost

Since the side of the fabric are baking in oven drying, it will not have difference between these 2 sides.

Fabric running is wavy shape, which completely realizes tension-free drying process, fabric will be fully retracted.

Each Chamber has a fresh air filling port for adjusting air volume; ensure the indoor air contamination is maintained in efficient condition.

The mesh belt has the function of automatic pneumatic rectify deviation, sensing running conditions of mesh belt, maintain mesh belt’s reliability.

High efficient heat exchanger is made by extrusion steel and Al composited tube, high efficiency.

High density thermal insulation of rock wool, and well moisture-keep performance

PLC+PMU operation panel, natural gas, conducting oil, steaming, 3 heating manner

High fiber feeding and mechanical centering padder can be in sync with the main machine.

Application

This machine is suitable for drying and sanforising process of tubular fabric and open-width fabric, etc.

Technical parameters

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)