|

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD

|

Gold Index: 8140

1.5kw Gauze batching machine / scouring and bleaching machine seamless steel

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

KD000-120 gauze batching machine

<p style="text-align:ce

KD000-120 gauze batching machine

KD000-120 gauze batching machine / scouring and bleaching machine / batching machine used for gauze

1. Application:

This machine can be used for batching of medical gauze before scouring and bleaching.

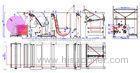

1. Process –flow: Debatching →batching (refer to attached drawing)

2. Main specification

- Fabric width: ≤1200mm

- Mechanical speed: 1070m/min

- Machine type: Left hand or right hand

- Winding diameter: 700mm

- Available compressed air: ≤0.4MPa

- Dragging method: AC frequency conversion

- Total power: 1.5kw

3. Structure feature:

It consists of machine frame,transitional guide roller,transmission parts,pneumatic pressurized device,initiative compression roller and winding roller,pivot,debatching shaft,tension control device and so on.

- Machine frame: the middle vertical column adopts 280×82mm channel steel, connected by transverse rail. Both sides made from 140×6mm channel steel, bearing base set up two platforms, swing arm made by armor plate hem. The whole machine frame is stable and deep-set.

- Transitional guide roller: the upper guide roller diameter is 125mm; the two transitional guide rollers has 100mm diameter.

- Transmission parts: the initiative press roller rotary by means of 1.5kw AC motor connected reducer directly through dragging transmission shaft.

- Pneumatic pressurized device: consists of oil atomizer,decompress valve,manometer,directional valve,2 perform vat and joint etc.

- Initiative compression roller: diameter 220mm. made of A3 seamless steel tube(φ219×10mm)wrapped by 2.5mm stainless steel plate for external.

- Winding roller: made of 3mm stainless steel plate, mesh diameter: 8mm

- Density : 5102/² Weld cover at both side, not only easy for pivot inserting ,but also ensure fluid flow when scouring and bleaching.

- Tension control device: tension valve decided by electric part and performed by magnetic powder clutch.

2. Installation and adjusting:

1. Mark centre line for installation in compliance with foundation plan; make sure all of foundations hole according to centre line and mark the other part’s centre line.

2. Make sure every foundation hole per required size and depth.

3. Keep flat and tidy about concrete surface.

4. Set up foundation bolt to soleplate and put it to foundation hole, install machine frame.

5. Machine frame‘s central line must overlap with groundsill’s central line, adjust bearing iron and adjustable bolt horizontally, across wrap of machine frame should upright with groundsill’s central line.

6. Make sure the lever and parallel degree about machine frame installation by means of line coordinates

7. Install other parts on machine frame and make sure the level and parallel degree.

8. Install guide roller, all of them must keep level and parallel with each other.

9. Fill concrete in foundation hole. Make sure the uprightness of foundation bolt.

10.Make sure the level and parallel degree of all guide roller, and keep it flexible. Moving parts can be flexibly install and remove. Make sure the tightness of chain wheel.

11. Connect electric circuitry

12. Screw down foundation bolt after concreting, check level degree.

13. Complete external pipeline installation, electric and compressed air is ready for operation.

3. Preparation and operation

Check the lubrication about bearing and reducer completely, and keep the cleanness of guide roller.

Commissioning: Insert the debatching shaft to liner pipe and adjust it to middle position, lift the cloth coil and make the debatching shaft parallel with fixation shaft, moving the cover to debatching shaft and tighten it.

Test-run with cloth: check the machine when run in cloth guide speed, rise to rated mechanical speed gradually when it’s under normal condition,

Set up and adjust tension valve, inspect the variation of fabric’s tension.

4. Maintenance

- Take the cloth to storage rack after coiling, remove the bearing,chuck and pivot.

- Turn off power supply and gas supply; clean the surface of guide roller.

- Lubricate every bearing and transmission chain regularly.

- Check every bearing, repair or replace it timely.

- Check magnetic power clutch regularly, repair or replace it timely

- Turn off general power supply timely when stopped machine.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)