|

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD

|

Gold Index: 8140

High-press Jigger Dyeing Machine

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High-temp High-press Jigger Dyeing Machine

KD-GR120-360 High-temperature High-pre

High-temp High-press Jigger Dyeing Machine

KD-GR120-360 High-temperature High-pressure Automatic Dye Jigger

Introduction

This dyeing equipment manufactured by our factory, is suitable for various synthetic, cotton and linen fabrics to be dyed with distributed, sulfur, vat, direct, and reactive dyes, scoured, soaped and cleansed at a constant rate and under a constant tension. It has the features of advanced design, reasonable structure, and superior performance, safe and reliable operation.

Main Technical Parameter

Max. Diameter of cloth roll: Φ1200mm

Max. Working fabric width: 2000mm

Adjustable fabric tension: 0~60kg

Adjustable fabric rate: 20~80m/min

Diameter of main roller: Φ220mm

Max working pressure: 0.4Mpa

Max working temperature: 140

Liquor ratio: 1:2

- Technical feature

- The total machine adopts computer CAD added design; CAM added amylases, high precision manufacture.

- The total machine adopts AC frequency conversion (servo) drive to control fabric tension and speed. The whole control system is with big adjustment range, reliable operation, low failure rate, low maintenance difficulty.

- Constant line speed,constant tension online control, primarily eliminate aberration,color cast during dyeing process; accurate temperature control fit different technological parameter request.

- Precise temperature control fit different technological parameter request, overhead warming and warm-keeping device to ensure warming rate and improve produce efficiency.

- In the machine electrical control system designed with automatic reversing,passage counting,length counting,passage full automatic stop or changed into automatic manipulate function.

- The whole machine equipped with overhead floodlight for convenient operation and maintenance.

This system cans automatic charge according to technology request to reduce fabric front and back chromatist and improve yield.

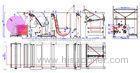

Main structure

- Transmission mechanism

The whole machine drives by two AC motors through pulley drives gear reducer, reduction box and cloth roller connected by flexibility coupling, this type separating structure is easy to operation, dismantling and installation.

- Dye vat

Dye vat is made of 1Cr18Ni9Ti stainless steel, the dye vat adopts double bottom roller to drive, extend the time of fabric in the dye liquor,increased fabric dyeing efficiency; cell body center installed velocity measurement roller which can measure speed,count length,check fabric tensioncell body bottom installed dye liquor circulation device to make inside temperature and liquor stirring evenness and remove fabric crosswise chromatist.

- Width expansion frame

In order to prevent wrinkle during dyeing process,install spring type width expansion frame inside the cell bodywidth expansion frame is made of stainless steel,composited of swing arm,width expansion roller,cloth guide roller,tension spring etc.

Tension spring is made of 4Cr13,with good mechanical characteristic and corrosion resistance.

- Water,steam pipe system

Inflow parts is composited of water inlet,water inlet spray and mating valves, user can control according to actual inquiry.

Total machine steam pipe is mainly composited of cell body thermal insulation coil,cell body direct heat pipe and mating valvescell body direct heat pipe is automatic controlled by pneumatic thin film valve.

- Output mechanism(selective purchasing part)

Total machine output has two types: cross arm output and A frame driven output, user choose any type.

Cross arm output installed in the total machine, composited of cross arm,motor,cylinder,rubber roller, output motor thought worm wheel retarding mechanism to drive rubber roller, then rubber roller hold down the A frame rolling roller to friction output.

“A” frame output is composited of drive frame,motor reducing box,universal joint cross,A frame etc.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi Kang Da Printing & Dyeing Equipment Co.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)